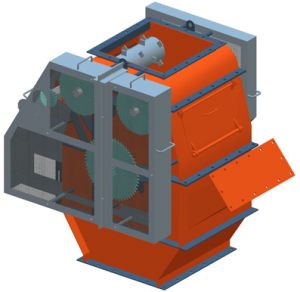

Fuel Metering Equipment 3-Drum Feeders

SCS has leveraged over 20 years of service to the sugar industry to develop a 3-Drum Feeders design that has been proven, through its more than 30 installations, to greatly improve both overall boiler emission rates and efficiency.

SCS’s 3-drum feeders work as a monitored mechanical feeding device. First, it utilizes a multiple drum approach to ensure a consistent texture and quantity, then it employs mechanical paddles to distribute bagasse onto the grate for a more uniform and efficient burn. It is proven to be superior to antiquated solutions such as air blowers and single drum feeders, which provide inconsistent and difficult to burn piles of bagasse on the grate.

As with all SCS fabricated equipment, customized options are limitless, and the equipment is of the highest quality available in the marketplace. SCS can manage the entire lifecycle of the project with a turn-key solution or can deliver equipment and services in an a la carte fashion.

Features

- Industry proven design with uniform fuel metering

- Fully customized to customer specification & process

- Entire project lifecycle managed with SCS employees

- Experienced in-house engineering, fabrication & construction teams

Available Services

- Full turn-key capabilities

- Complete piping designs, foundations and electrical upon request

- Stress analysis

- Construction & engineering capabilities beyond integration points

- Full range of aftermarket services

- Quick deliveries based on production schedules

Benefits

- Improves system efficiency through sealing furnace from tramp air

- Decreases maintenance cost through elimination of fuel choking

- Requires less horsepower than traditional solutions

- Creates an optimum performance environment in the furnace and greater efficiency overall through accurate fuel metering

- Long product life (average 20+ years)

- Significantly reduced maintenance & downtime costs