Solid Fuel Boilers Stoker Grate Boiler Systems

SCS brings over 24 years of experience and unparalleled quality to the utility and industrial grade boiler marketplace in stoker grate combustion solutions in the output range of 10K PPH to 500K PPH. SCS can provide the full scope of engagement to deliver a turn-key power or cogeneration plant including engineering, design, fabrication, procurement, construction, balance of plant work and aftermarket services.

A variety of stoker grate combustion options are available depending on the operating parameters and fuel specified. Common options include vibrating, traveling, stationary and reciprocating grates.

Benefits

- Low capital costs – SCS has the reputation for offering the highest quality equipment at the best possible value. Customers using stoker grate combustion technology often realize the lowest possible initial capital costs.

- Low maintenance costs – Grate technology offers simple operation and reduced maintenance costs.

- Less refractory – As it requires less refractory in the furnace and boiler, emergency and planned outages have reduced maintenance costs.

- Availability – Grate technology provides the lowest available system downtimes of any combustion technologies.

- Fuel flexibility – Grate technology is the best option for fuels with moisture content under 55%, low ash fusion fuels and high alkali content fuels which cause slagging in BFB/CFB systems.

Boiler Types

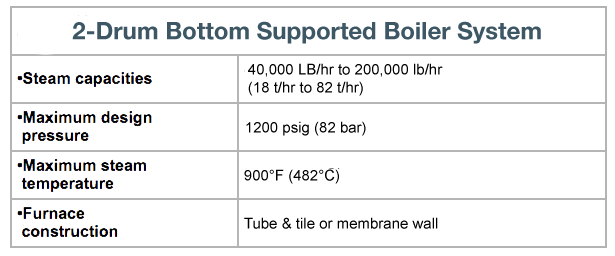

The 2-drum bottom-supported boiler is offered in a wide variety of fuel firing combinations including gas/oil burners, solid fuel suspension burners (for sander-dust), and continuous ash discharge stokers including traveling grate, air and water-cooled vibrating grates.

The furnace and the boiler are designed for the specific requirements of the fuels to be fired and boiler operating conditions. The furnaces are conservatively sized to improve fuel combustion and burnout, reduce particulate emissions carryover, and provide low furnace volume heat release rates.

By having two gas passes through the boiler bank, the boiler exit gas temperature is lower than a top-supported single gas pass boiler design. This results in a smaller tubular air heater and/or economizer.

For superheated steam applications, a radiant and/or convective pendant type superheater can be provided.

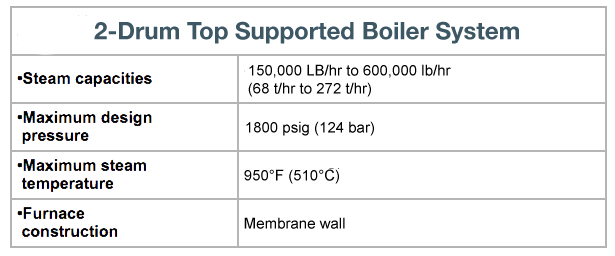

The 2-drum top-supported boiler is offered in a wide variety of fuel firing combinations including gas/oil burners, solid fuel suspension burners (for rice hulls and sanderdust), and continuous ash discharge stokers including traveling grate, air and water-cooled vibrating grates.

The furnace and boiler dimensions including height, width and depth and drum centers are selected and optimized for the specific requirements of the fuels to be fired and the boiler operating conditions. The furnaces are conservatively sized to improve fuel combustion and burnout, reduce particulate emissions carryover, and provide low furnace volume heat release rates.

Radiant/convective superheaters are designed to provide the required steam outlet temperature over the required load range. The superheaters are a pendant design located prior to the convection bank.

When to Choose a Stoker Boiler

- Low capital costs are paramount

- Low operations & maintenance cost are targeted

- When a customer expects to burn fuels with either of the following conditions:

- Low ash fusion temperatures in the fuel

- High alkali content in the fuel

Fuel Options in a Stoker Grate Boiler

- Agricultural residue (bagasse, stover, rice hulls)

- Bark

- Biomass

- Coal

- Landfill gas

- Natural gas

- Oil

- Paper mill sludge

- Peat

- Poultry litter

- Process wastes (furniture manufacturing, construction & demolition)

- Recycled paper facility sludge

- Tire-derived fuels

- Wood waste (forestry, pulp and paper)

- And other fuels